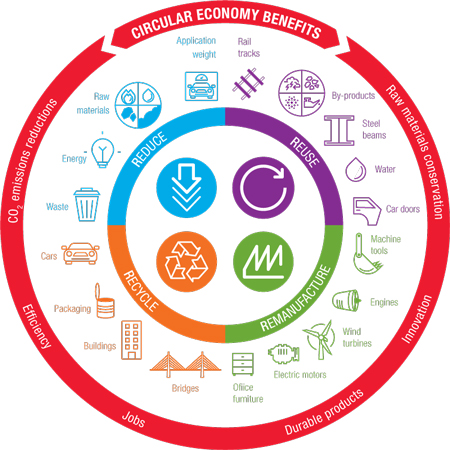

The circular economy is an emerging economic model that aims to minimize waste and maximize the value of products and materials by reusing, repairing, or recycling them. Unlike the traditional …

Circular Economy: The Key to a Sustainable Future

The concept of circular economy aims to transform our current economy, based on mass production and consumption, into a more sustainable and environmentally-friendly model. Instead of producing waste that is …

The role of inventory for recycled material in a financial audit.

To demonstrate their financial integrity, companies occasionally undergo an accounting and financial audit. The financial state of a company must be examined to ensure everything is in order and to …

Improve the energy efficiency of your company.

People use energy for variety of purposes, including transportation, cooking, heating and cooling rooms, manufacturing, lighting, and entertainment. People’s choices about how they use energy, such as turning off machines …

The benefits of reverse logistics

Reverse logistics refers to the process of planning and managing the return of consumer goods (end users) to the manufacturer or distributor for recovery, repair, recycling, or even disposal. Reverse …