« Industries are aware of raw materials battle is a competitiveness and market sustainability battle» Nowadays, a crisis is a popular word in business in spites of its despicable meaning, something …

Circular Economy, why Canada should try this model?

Inspired from an interesting article that connects two different country realities China’s Disastrous Pollution Problem Is a Lesson for Canada With almost 10 million km2 of surface Canada occupies the …

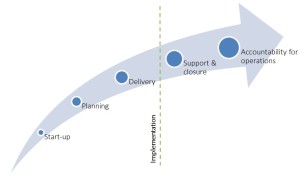

Circular economy can be overwhelming

“Change is hard at the beginning, messy in the middle and gorgeous at the end” Robin Sharma Adult life brings us new challenges and one of the is “changes vs habits”, I …

Turbulence is blowing off air transport industry to circular economy

While thinking about my new blog subject I bump into a turbulent territory Air transport industry. As we all know this sector has been through a decade-long recession and there …